PRECISE

INTER-ROW CULTICATION,

EXTRA

STRONG

FRAME

BUSA™

Mounted

Forestry

Discs

Advantages of the BUSA™ Mounted Forestry Disc Harrows

Precise inter-row cultivation

Extra strong frame

Flexible placement

History of the product family

What exactly is a Mounted Forestry Disc Harrow?

In this product category, you can find various implement designs.

Under forestry conditions, there is a need for special solutions. It is crucial that the implement can withstand extreme loads while considering that the specific area may not necessarily allow for large power units.

We offer solutions for cultivating plantations with side-shifted discs, for tending seedlings with our specially designed X-discs, and for more challenging forestry conditions with our reinforced-frame V-discs.

In the case of Mounted Forestry Disc Harrows, the same is true: the axle of the disc unit is square in cross-section, and the discs also have square holes, ensuring the synchronized movement of the two units. Spacers are inserted onto the axle to attach the discs, securing them with the axle end nut. The axle ends are tightened with the axle end nut for the required compression.

Each discs comes with a mud scraper, ensuring that even wetter soil poses no problem for the implement. These implements have a simple and robust design, always equipped with IH system self-aligning ball bearings. The angle of the disc rows on the V-disc Harrows can be adjusted continuously, allowing for effective penetration into various soil types.

What kind of configurations are available?

- Frame

- Disc row 1.

- Disc row 2.

- Finisher

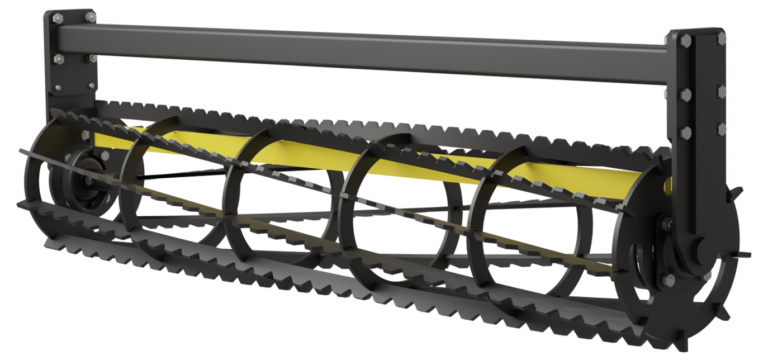

Slated roller

A clod breaking roller, typically used on Rotary seedbed makers and Disc harrows. It creates a fine clod structure on the surface while providing light compaction beneath. For wet soils, early spring…

seedbed preparation, we recommend the version with our patented internal scraper.

Slated roller

A clod breaking roller, typically used on Rotary seedbed makers and Disc harrows. It creates a fine clod structure on the surface while providing light compaction beneath. For wet soils, early spring…

seedbed preparation, we recommend the version with our patented internal scraper.

Frame structure categories

SX - Row Crop Cultivation Disc

The row-cultivating disc consists of 4 disc units.

The guiding plates are responsible for maintaining precise row spacing, avoiding ridge formation, and protecting the plants. They prevent the disc bases from ‘throwing’ soil onto the cultivated plants.

The machine is available in fixed or foldable versions.

SX-K - Row Crop Cultivation Disc

The stronger, more easily adjustable version of our SX series. These discs are fitted with 510 – 560 mm disc pads. Optionally available with extra strong pads…

the standard thickness is 5 mm, but 6, 7, and even 8 mm are possible.

The system can be ordered with 4×4-5-6 leaves, 200 or 225mm pitch.

The machine has swivel joints for angle adjustment, so the grip is rigid and the angle adjustment is easy with a spindle. Of course, the machine maintains the center line of the front and rear disc rows, so the overlap is secure.

The distance between the two rows can be adjusted with two spindles. The machine is actually two halves of a small disc, and the two small discs can be adjusted laterally with two spindles.

OT - Offset Disc

At the plantations, in certain cases the machine is required to be offsetted, in this way it is possible to approach the plants, without damaging them with the tractors.

UTN - Heavy Forestry Disc

Our Mounted V-disc Harrows with a reinforced frame and 560 mm disc blades are commonly used in forestry applications.

Working with a trailed machine is easier because it allows for turning without lifting, better longitudinal stability, but there are cases where the mounted version is an essential compromise.

UTNN - Heavy Forestry Disc

Our Mounted V-disc Harrows with a reinforced frame and 610 or 670 mm disc blades are commonly used in forestry applications.

Working with a trailed machine is easier because it allows for turning without lifting, better longitudinal stability, but there are cases where the mounted version is an essential compromise.

UTIN - Super Heavy Forestry Disc

Our Mounted V-disc Harrows with a reinforced frame and 710 mm disc blades are commonly used in forestry applications.

Working with a trailed machine is easier because it allows for turning without lifting, better longitudinal stability, but there are cases where the mounted version is an essential compromise.

Comparison

Technical data

-

BUSA™ SX

-

BUSA™ SX-K

-

BUSA™ OT

-

BUSA™ UTN

-

BUSA™ UTNN

-

BUSA™ UTIN

Want a quote?

Pictures and Videos

Frequently asked questions

If the cultivation of the space between rows of seedlings is the task, then the SX implement is the ideal solution. The seedlings run beneath the tractor, while the disc rows work in the inter-rows.

At the plantations, in certain cases the machine is required to be offsetted, in this way it is possible to approach the plants, without damaging them with the tractors. For this operation we recomend our OT Disc Harrow.

In all cases, they are equipped with IH system self-aligning ball bearings.

Each discs comes with a mud scraper, ensuring that even wetter soil poses no problem for the implement.

The guiding plates are responsible for maintaining precise row spacing, avoiding ridge formation, and protecting the plants. They prevent the disc bases from ‘throwing’ soil onto the cultivated plants.

It is equipped with 560 mm discs.

It is equipped with 710 mm discs.

The OT Disc Harrow needs to be positioned to the side manually.

You can request our Forestry Disc Harrows with either a slated roller or a spiral angle profile roller.

We use Belota manufactured discs on our disc harrows, except for the 485 mm size, as the depth of discs available in the market, in this size proved insufficient for the required working quality. Therefore, we manufacture this size ourselves.

You can always count on us!

- Reference, machine demonstration

- Brochures, leaflets

- Machine setup

- Warranty management

- Spare parts

- Used machines